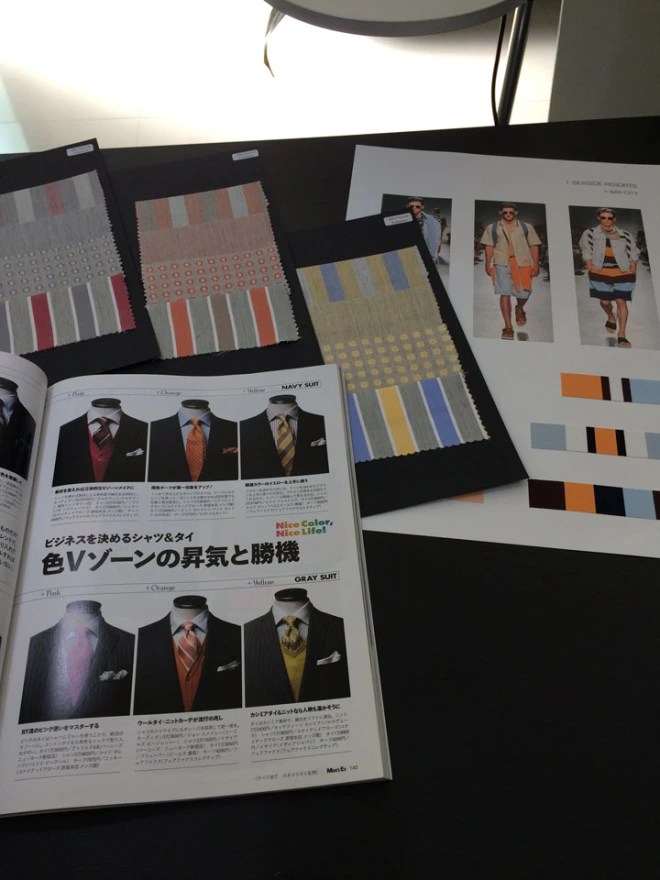

At the beginning of the collection making process there is information gathering.

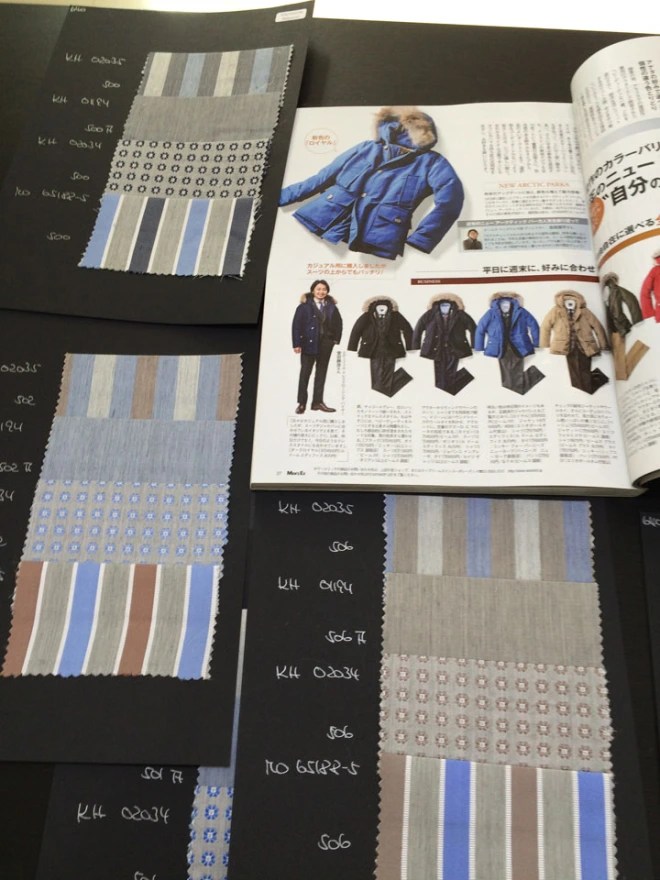

We visit fairs, study specialized magazines, do retail survey and most importantly are in constant exchange with our customers.

Doing so we are can get an idea what the upcoming trends in colors and designs most likely will be.

Freelance designers are called in, people specifically educated and trained for the necktie industry as they need to consider the technical feasibilty of our design instructions.

These designers convert our information and ideas into artwork .

For jacquard that looks as follows:

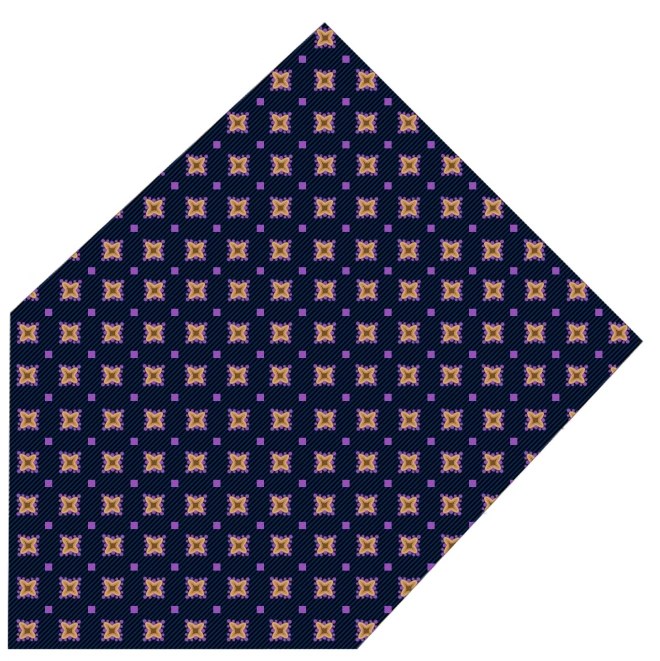

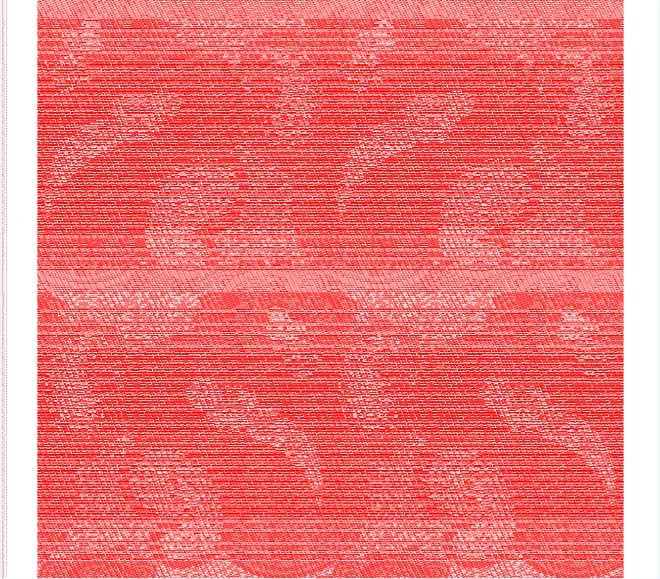

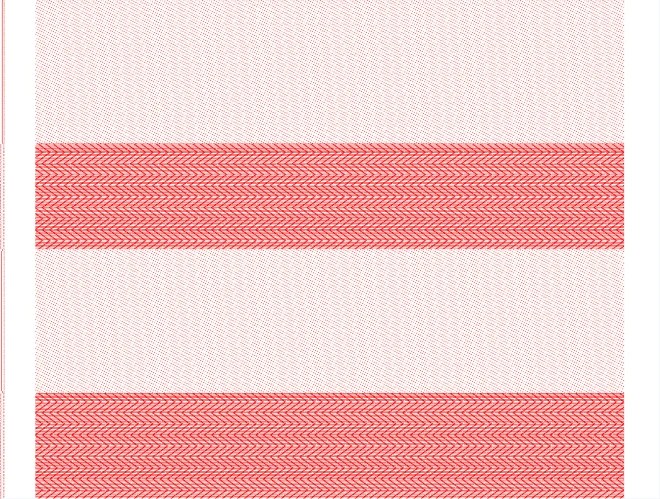

Artwork example 1, various types of bindings within the repeat

Artwork example 2, one type of binding within the repeat, linen look

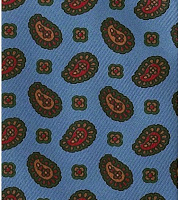

Artwork example 3, all over on simple twill

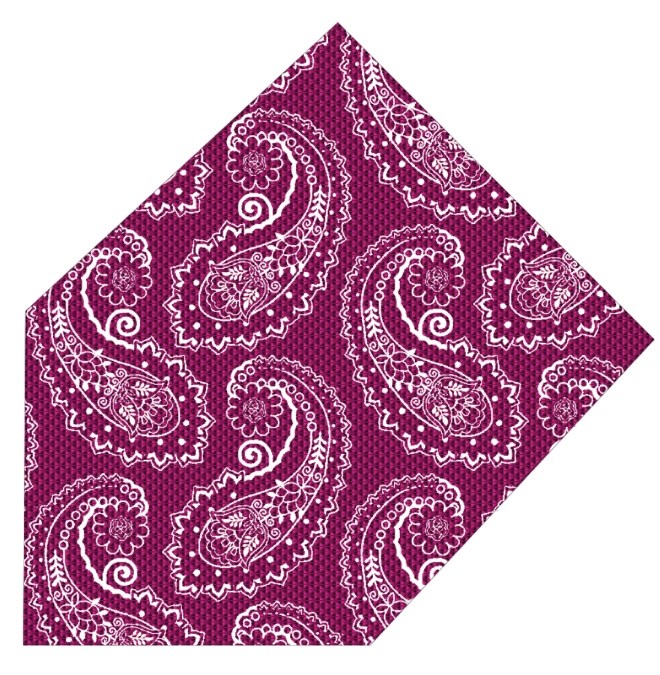

Artwork example 4, paisley on textured ground

After we have decided which designs we take into our collection we call in freelancer technicians, again highly educated and trained people especially for our industry with decades of experience.

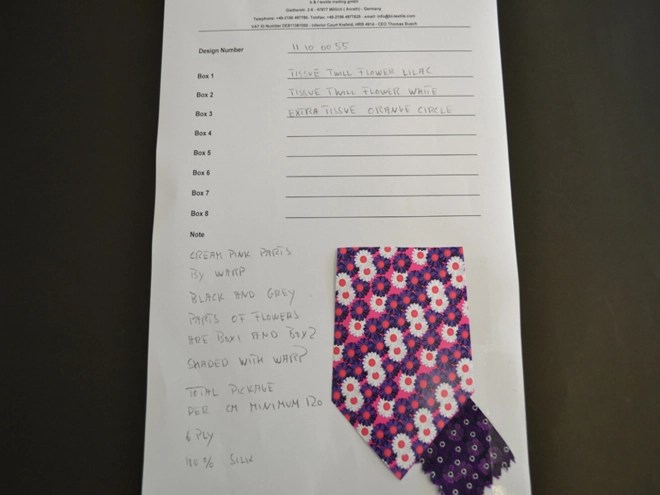

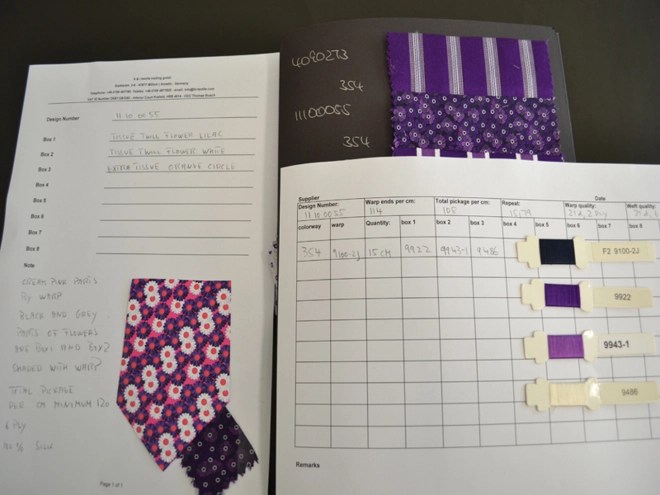

According to our information which we inform the technicians on our design sheets,

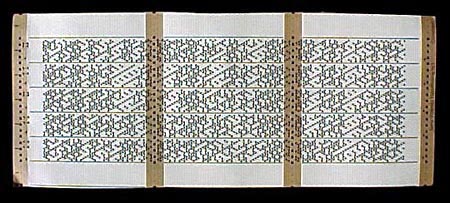

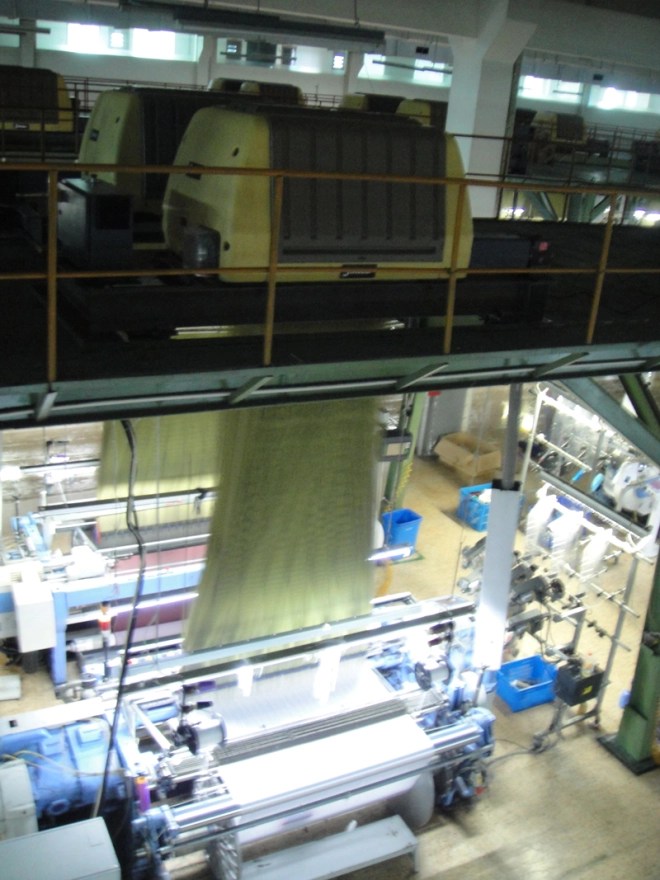

they techncians transforms the artwork into a technical information, the cartridge. The cartridge contains the information that the weaver needs to input into the loom for it be able to weave that particular design.

Before the digital revolution this information was obtained as so called paper jacquard.

Nowadays this information is obtained in digital form – simply as a file.

and fed into the digital control unit of the loom:

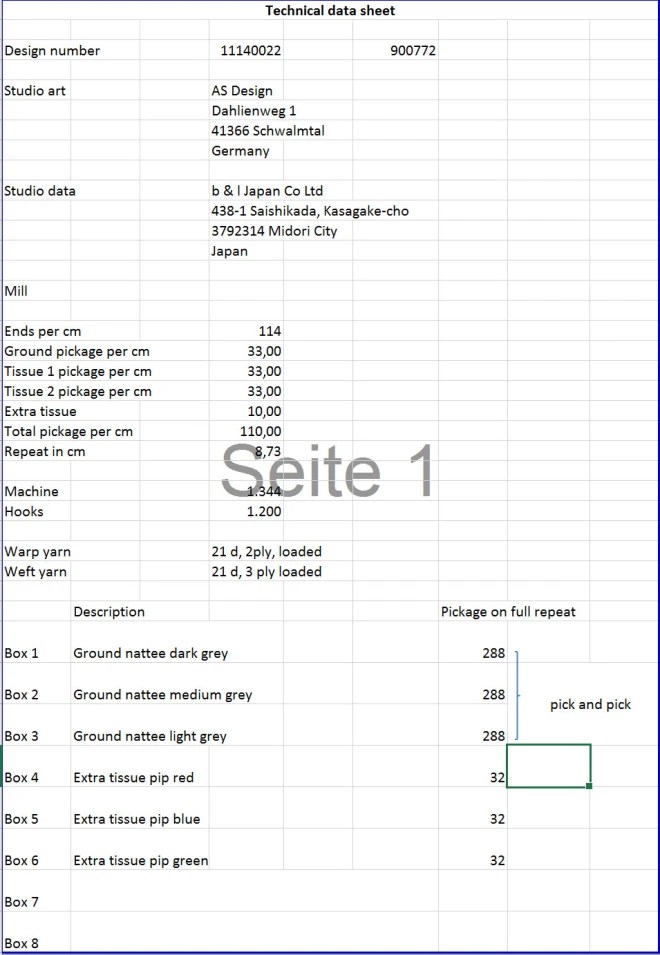

The technician also issues a so called technical data sheet which contains to the most important informations in written.

Such as the so called box motion for example, that allows us to color the designs:

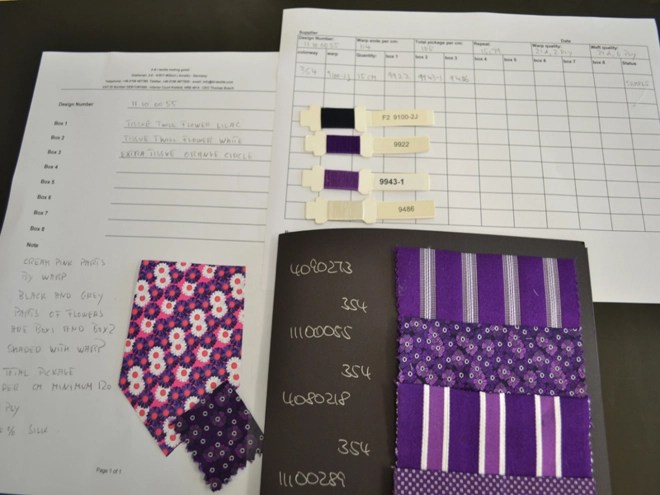

As the colors had been decided according to the information we gathered from fairs, magazines, retail survey and customer communication we create color stories.

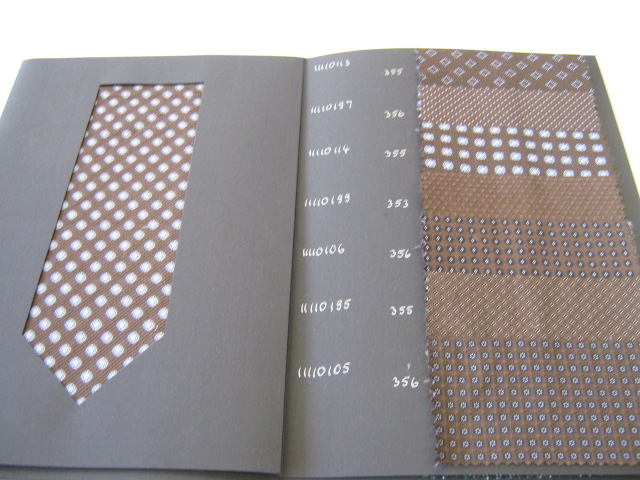

Usually we take up to 6 different designs to be arranged on one presentation card board and have them in one color level.

At our back office preparing the collection:

Matched design and color stories following customer’s request for an autumn / winter line and a small ceremonial selection, part 1.

Matched design and color stories following customer’s request for an autumn / winter line, part 2.

Further design and color stories upon customer’s instruction for the more commercial markets, part 1.

Further design and color stories upon customer’s instruction for the more commercial markets, part 2.

Further design and color stories upon customer’s instruction for the more commercial markets, part 3.

Mrs Yan Song, Managing Director. Her strength next to many is to maintain always a calm and controlled attitude in a business in which there is always time pressure. She masters all facets of international trade, bureaucratic as well as regulatory tasks and continues to provide service exactly at that point of time where our competitors or yet even suppliers refuse to go on.

Trimming of fabric cuttings for all design and color stories completed. Next step is the attachment on the card board.

Two examples on how customers prefer card boards to be made.

Thomas Busch Japan also does prints. And the process of collection making in terms of information gathering is of course identical to jacquard.

In China as well as in Italy, application print is dominant. Application print allows vivid and strong colors as opposed to discharge print. With discharge printing colors appear timid and dull.

This means that the ground colour is discharged into the silk first, creating a background that the pattern is printed on. So the background may be dyed navy and then red spots, say, discharged onto the silk. As the pattern has to discharge through the silk, it is a tricky process – too heavy and it will soak through, too light and it won’t sit in the material.

The alternative, application print, the pattern is always printed on a white background. So the navy is printed as a pattern that leaves spaces for the spots; then the red spots are printed in those spaces separately. It is cleaner and easier.

The resulting optic is sharper and brighter. Think of a classic Ferragamo tie, or an Hermes print – those are done with the Italian method and are generally sharper than discharged printed neckties

Medium sized twill grey cloth, 36 oz, discharge printed.

Medium sized twill grey cloth, 36 oz, discharge printed.

Super fine twill, 36 mm. application print.

Super fine twill, 36 mm. application print.

So it depends on customers request, market, fashion what type of printing is employed.

When ordering artwork for prints, we can enjoy more freedom as there are no technical restrictions, such as repeats to consider.

Furthermore there are basically no restrictions to the total amount of colors that can be applied, whereas in jacquard wovens we can work up to maximum of 9 colors, one warp and 8 weft.

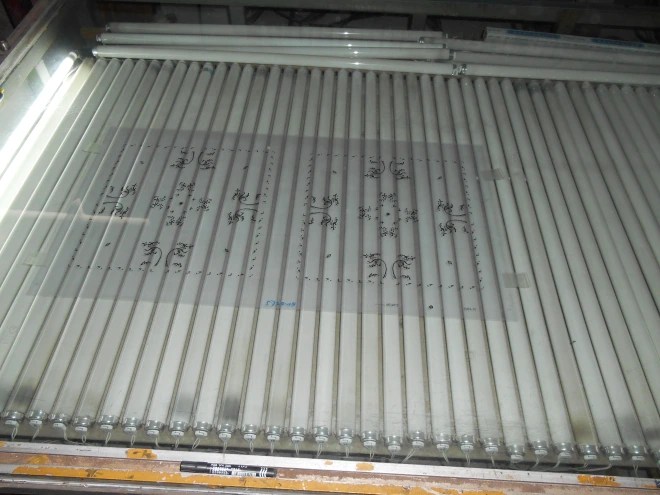

Once an artwork is selected we instruct the so called screen rotation.

Each chosen color represents one screen.

Picture

With this information the factory will start to actually produce the screens by which the pattern and color(s) will be printed onto the grey cloth.

Textile printing is related to dyeing but in dyeing the whole fabric is uniformly covered with one colour, whereas in printing one or more colours are applied to it in certain parts only, and in sharply defined patterns.

In China we mostly still print by hand using screens.

Screen printing a printing technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

A blade is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed.

One color is printed at a time, so several screens are used to produce a multicoloured design. Below a demonstration video by Hermes which illustrates the the process nicely:

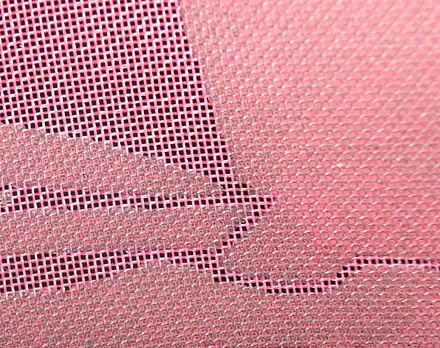

As a stencilling technique our Chinese partner employs the photo emulsion technique.

The different colors / screens of the original artwork are reproduced as a photo positive on a transparent overlay, leaving the areas not to be printed not transparent.

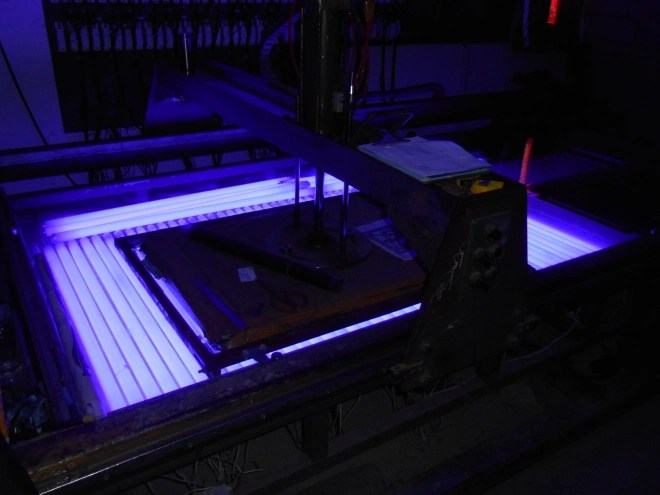

The screen will be coated with emulsion and put to dry in a dark room. Once dry, it is then possible to burn/expose the print.

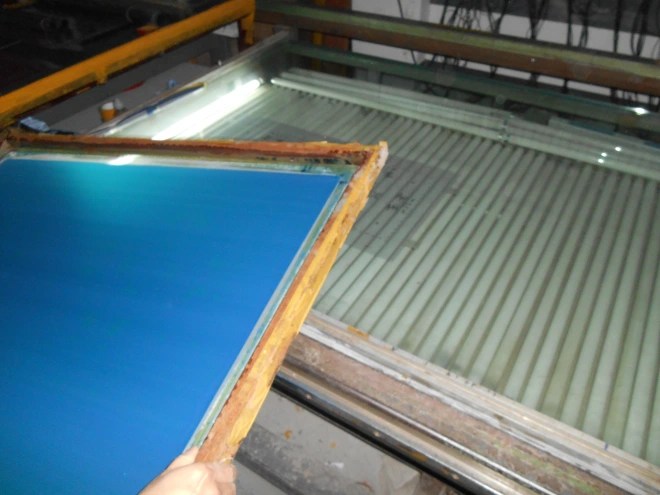

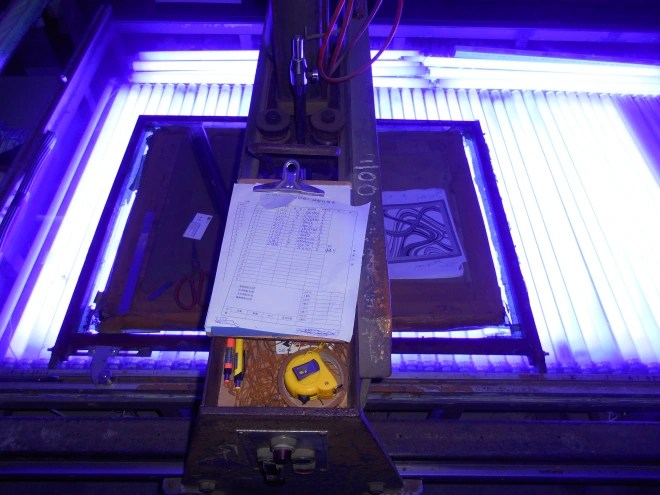

The photo positive / overlay is placed onto a light exposer unit.

Onto the overlay the screen is placed.

The photo postive is then exposed to a light source containing ultraviolet light in the 350-420 nano meter spectrum.

The screen is washed off thoroughly. The areas of emulsion that were not exposed to light dissolve and wash away, leaving a negative stencil of the image on the mesh.

Then the printing process can start.

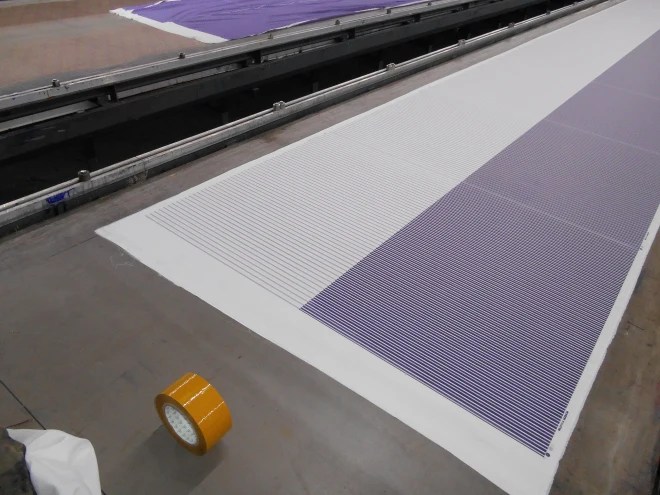

Here one can see the first screen printed on the grey cloth resulting in a fine pin stripe at the left side of the picture. The sceond screen printed the wider purple stripe on the grey cloth as to be seen on the right side of the picture.

One advantage of screen printing is that large quantities can be produced rapidly with new automatic presses.

One disadvantage is that these screen obviously require large warehouses to be stocked.

That is why our partners in China normally keep screens only for about to about 3 months and then dispose of them.

Repeat orders at a point of time later than 3 month require that screens have to be made again.

And so occur the costs to reproduce the screens.